TRANSFORMER

Transformers

• A transformer is a static device

that transforms electric energy from one ac voltage level to another. It is

this device that has made the electric system almost universally AC. The

electric power is generated at relatively low voltages (up to a maximum of 33

kV) which then is raised to very high voltages (e.g. 756 kV) by means of a

transformer and then transmitted.

• High voltages are associated with low

currents and reduced transmission losses.

• The core

which supports the transformers mechanically and conducts their mutual flux, is

normally made of highly permeable iron or steel alloy (cold-rolled, grain

oriented sheet steel). Such a transformer is generally called an iron-core

transformer.

• However in special cases, the magnetic

circuit linking the windings may be made of non-magnetic material, in which

case transformer is referred to as an air-core transformer.

• Air core

transformer used in radio devices and in certain types of measuring and testing

instruments.

• The

magnetic core of the transformer is made up of stacks of thin lamination of

0.35 mm thickness of CRGO lightly insulated with varnish, this material allow

the use of high flux density [ 1-1.5 T] and its low loss property together with

laminated core reduces the core loss to fairly low values.

Core Type

transformer: -

• In core

type transformer windings are around two legs or three legs (depend on their

phases) of the rectangular magnetic core.

•

Rectangular magnetic core is made by using the E and L shape of the sheets.

• Though

most of the is confined to a high permeability core, some flux always leaks

through the core and lies in air called leakage flux.

• Leakage is reduced by bringing the two coils

closer. In core type we achieve this by using L.V. and H.V. on each limb of the

core.

Shell type

transformers: -

• In this

type of the transformer windings are wound on the central leg of a three legged

core.

• Leakage in

shell type transformer is reduced by sub-dividing each winding into sub-section

and interleaved in L.V. and H.V winding.

Conservator:

-

Power

transformer is provided with a conservative through which transformer breaths

into air. It is a small size tank placed on the top of main tank. It prevents

fast oxidization and consequent deterioration of insulating properties of oil.

Explosion

vent tube: -

Purpose of this is to prevent damage of

transformer tank be releasing any excessive pressure generated inside the

transformer.

Radiator: -

- When an electrical transformer is loaded, the current starts

flowing through its windings. Due to this flowing of electric current, heat is

produced in the windings, this heat ultimately rises the temperature of

transformer oil. Hence, if the temperature rise of the transformer insulating

oil is controlled, the capacity or rating of transformer can be extended up to

significant range. The radiator of transformer accelerates the cooling rate of

transformer. Thus, it plays a vital role in increasing loading capacity of an

electrical transformer. This is basic function of radiator of an electrical

power transformer.

- The working principle of radiator is very simple. It

just increases the surface area for dissipating heat of the oil. It is used in

large size transformers

Breather: -

• When the

temperature change occurs in transformer oil, the oil expands or contracts.

There is an exchange of air also occur when transformer is fully loaded.

• When the

transformer gets cooled then oil level gets down and when it goes down it

absorbs air this process is called breathing.

• Silica gel

breather controls the level of moisture. Silica gel is used to absorb moisture

content from air.

• When

silica gel absorbs moisture, it becomes pink. Generally, its colour is blue.

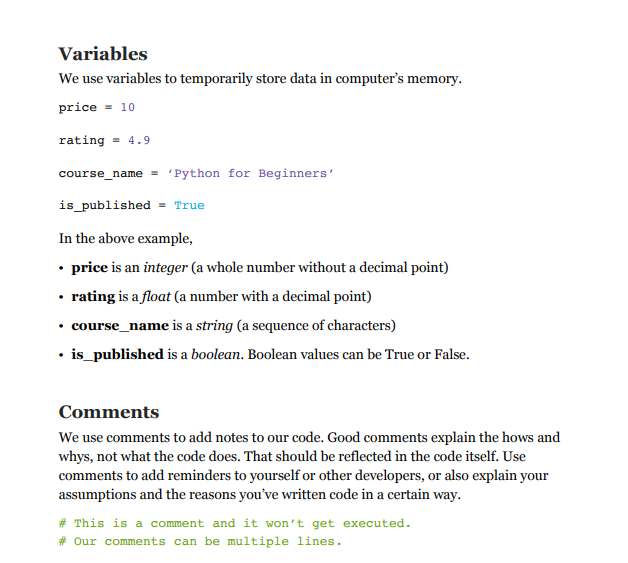

E.M.F.

equation: -

When a

sinusoidal voltage is applied to the primary winding of a transformer,

alternating flux ϕm sets up in the iron core of the transformer. This

sinusoidal flux links with both primary and secondary winding. The function of

flux is a sine function. The rate of change of flux with respect to time is

derived mathematically.

The derivation of EMF Equation of the transformer is

shown below. Let ϕm be the maximum value of flux in Weber. f be the supply

frequency in Hz. N1 is the number of turns in the primary winding. N2 is the

number of turns in the secondary winding.

As shown in

the above figure that the flux changes from + ϕm to – ϕm in half a cycle of

1/2f seconds.

By Faraday’s Law,

Let E1 is the e.m.f induced in the primary

winding

E1 = − dλ /dt

Where λ= N1ɸ

Therefore,

E1 = − N1/ dɸ dt

Since ϕ is

due to AC supply ϕ = ϕm Sinωt

E1 = − N1 d /dt

(ϕm Sinωt)

E1 = − N1 ϕm ω Cosωt

E1 = N1 ϕm ω Sin (ωt− 90°)

So the

induced e.m.f lags flux by 90 degrees.

Maximum

valve of e.m.f,

E1 = N1 ϕm ω

But ω = 2πf

(E1) max = 2πf N1 ϕm

Root mean

square RMS value is

E1= (E1)max √2 …………….(1)

Putting the

value of (E1)max in equation (1) we get

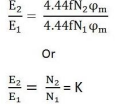

Now,

equating the equation (2) and (3) we get

The above

equation is called the turn ratio where K is known as transformation ratio.

Equivalent

circuit of the transformer: -

The

equivalent circuit diagram of any device can be quite helpful in

predetermination of the behaviour of the device under the various condition of

operation.

It is simply the circuit representation of the

equation describing the performance of the device.

The

simplified equivalent circuit of a transformer is drawn by representing all the

parameters of the transformer either on the secondary side or on the primary

side.

The equivalent circuit diagram of the

transformer is shown below

Let the

equivalent circuit of a transformer having the transformation ratio K = E2/E1

The induced e.m.f E1 is equal to the primary

applied voltage V1 less primary voltage drop.

This voltage

causes current I0 no load current in the primary winding of the transformer.

The value of no-load current is very small, and thus, it is neglected. Hence,

I1 = I1’. The no load current is further divided into two components called

magnetizing current (Im) and working current (Iw).

The secondary current I2 is

The terminal voltage V2 across the load is

equal to the induced e.m.f E2 in the secondary winding less voltage drop in the

secondary winding.

Equivalent circuit when all the

quantities are referred to primary side: -

In this case to draw the equivalent circuit of

the transformer all the quantities are to be referred to the primary as shown

in the figure below

The

following are the values of resistance and reactance given below Secondary

resistance referred to primary side is given as

The equivalent resistance referred to primary

side is given as

Req = R1 + R2 ’

Secondary

reactance referred to primary side is given as

The

equivalent reactance referred to primary side is given as

Xeq = X1 + X2 ’

Further

simplification of the equivalent circuit of the transformer can be done by

neglecting the parallel branch consisting R0 and X0. The simplified circuit

diagram of the transformer is shown below.

O.C. test

and S.C. test: -

The aim of

carrying out O.C. test and S.C. test on a transformer is to predict its

performance without actually loading it.

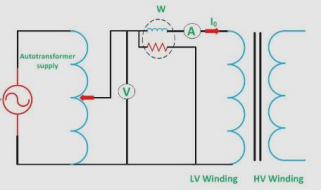

O.C. Test: -

O.C. test is carried out at rated frequency and rated

voltage to determine the core loss. The iron loss is thus is treated as

constant, in spite of minor voltage variation in voltage and frequency during

actual operation.

This test is carried out with the instruments placed

on low voltage side while the high voltage side is left open circuited.

This is done because it is easier to manage rated voltage

supply at low voltage level rather than at high voltage level. Also the

instruments used are economic in cost and it is easier to work on low voltage

side.

Therefore no load current is limited to 5% of full

load current, a primary winding copper loss is ignored, also the primary

impedance drop at such low current is neglected.

Because no load power factor is very low, it is recommended

that a low power factor wattmeter to be used.

Then the

iron loss of the transformer Pi = W0 and

The no-load

power factor is

S.C. Test: -

S. C. test

is carried out at rated current to determine the full load copper loss.

This test is carried out with the instrument placed

on high voltage side while the low voltage side is short circuited by a thin a

conductor (so that wire will not burn). This is because a rated current is

lower on low voltage side as compared to high voltage side.

Consequently, the instruments are economic in cost

since the voltage required to circulate full load current at circuited would be

about 10% of rated voltage.

The core loss under this low voltage condition is ignored. Also,

the exciting current at such low value of voltage will be completely neglected.

Short circuit test need not to be carried out strictly

at rated frequency because the copper loss that depends upon the winding

resistance is independent of the frequency of the supply as the skin effect in

transformer at power frequency is negligible.

Wattmeter used in this test is of high-power factor.